Case Studies of 4 Walls

Pumpkin Ridge

- Case Studies of 4 Walls:

- Glasswood

- Karuna

- Madrona

- Pumpkin Ridge

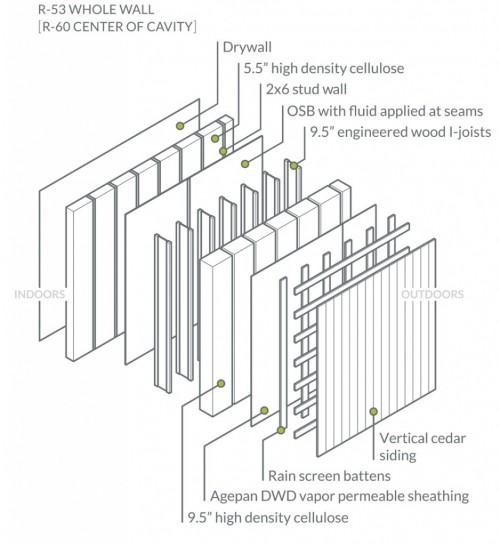

“Let’s do all cellulose,” is the story of the Pumpkin Ridge Passive House wall assembly. The design of the house became an expression of the home’s performance imperatives, so the display of thick walls, filled with several tons of high density cellulose insulation (and sequestered carbon), was seen by the team as a desirable design feature. The home’s energy performance is climate friendly, but so is its construction and low embodied energy.

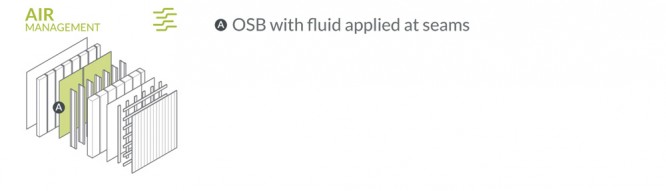

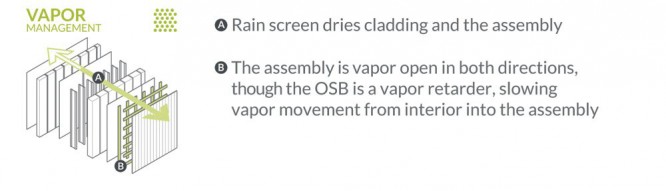

The air barrier for Pumpkin Ridge Passive House is a layer of OSB with fluid applied at seams. While the OSB is vapor permeable (and gets more so when wet), it does retard vapor transfer.

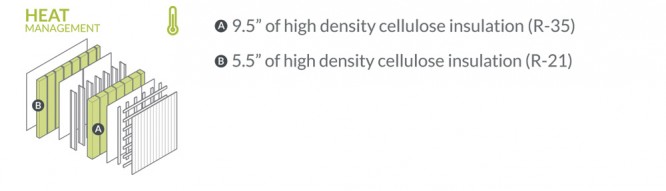

The wall’s R-60 insulative value (center of cavity, including impact of sheet goods and air films) is provided by two thick layers of high density cellulose insulation, 9.5” in a Larsen truss system to the exterior and 5.5” in the interior 2×6 stud wall.

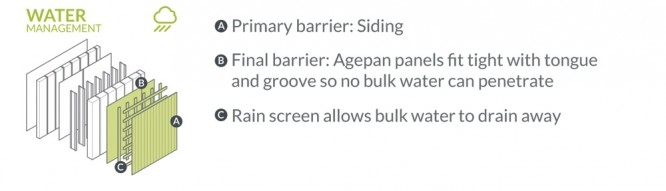

The home’s vertical cedar siding provides the first line of defense for bulk water management with a rain screen cavity facilitating drainage. The second (and final) barrier is the layer of tongue and groove Agepan (wax impregnated wood fiber) panels, tightly fit so that wind cannot blow bulk water through.

As mentioned earlier, the OSB is vapor permeable but it does retard vapor transfer. This throttles down the flow of vapor from the home’s interior into the assembly. The rest of the assembly, from cellulose insulation to Agepan layer, is very vapor open, so the airflow created across the assembly’s face by the ventilated rain screen cavity promotes the drying of both the assembly and the cladding.

See an annotated photo tour of the assembly’s layers: