With the Karuna House’s high performance foundation laid, our next step in building the green home’s advanced envelope was to create an airtight, watertight, vapor permeable, and super-insulated wall assembly. The goal? Control energy flow through the building while ensuring durability for the life of the structure.

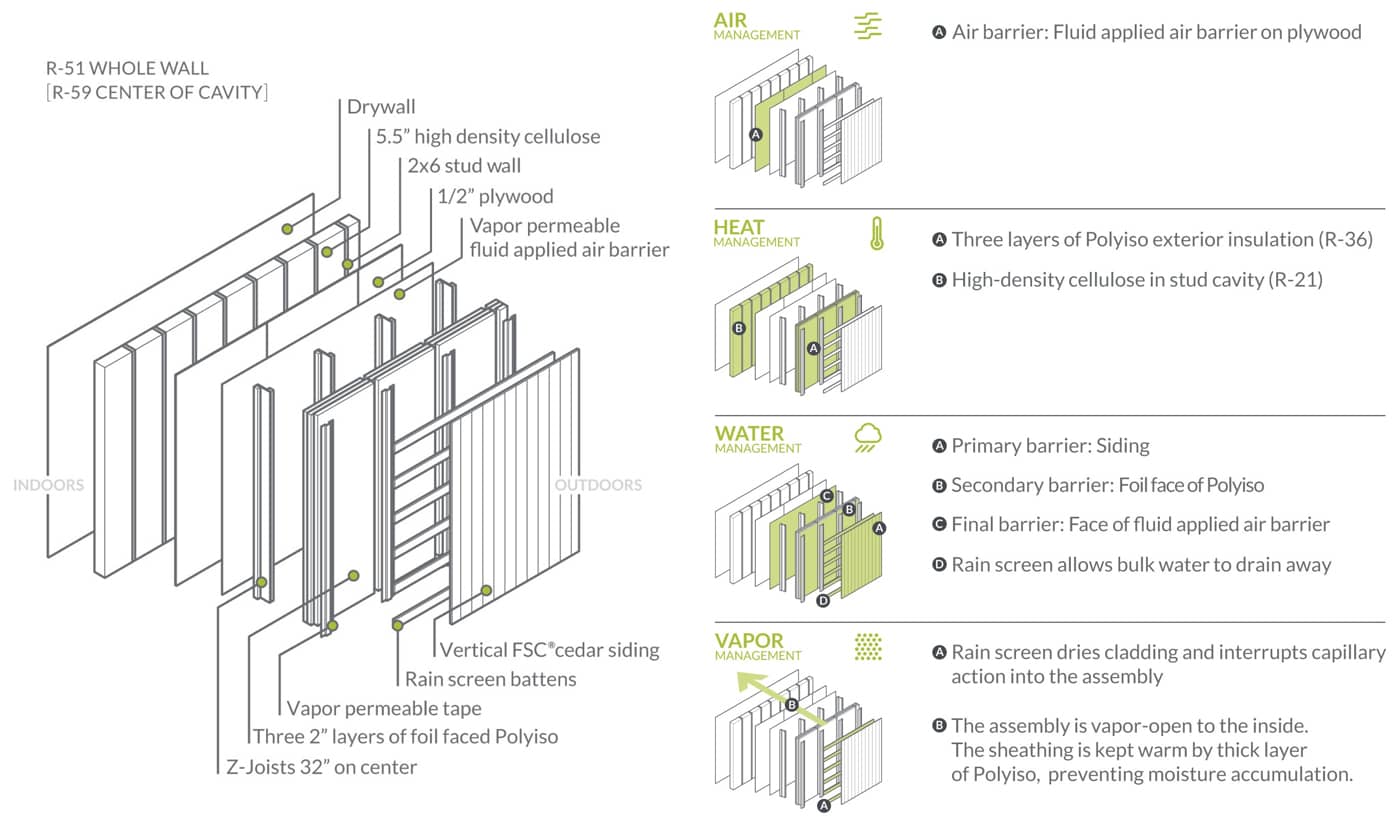

To do this, the team designed a wall assembly that carefully manages heat, air and moisture:

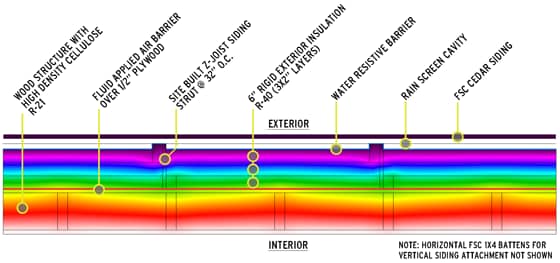

Starting from the interior edge of the assembly and working our way out…

Interior walls of the green building are finished with lime plaster, 100% natural and VOC-free, applied on 5/8” drywall. Next comes the stud wall, built entirely from Forest Stewardship Council® (FSC) certified wood, with high-density cellulose insulation (R-21) blown into the cavities between studs. (Though we built this stud wall from dimensional lumber, much of the green home building project is built with engineered wood to take advantage of the design flexibility and precision it affords – see “Cutting-edge framing is key to Karuna Passive House success.”) The cellulose insulation consists of recycled newspaper and naturally buffers moisture, contributing to the wall assembly’s durability. We used over 12 tons of the stuff at Karuna, easily dwarfing any other insulation used on the project, by weight.

See Project Supervisor Scott Gunter discuss installation of the cellulose insulation in this video:

Immediately outside the cellulose insulation layer comes the air barrier, one of the most critical elements of any high performance wall assembly. A ½” layer of plywood sheathing covered with a continuous, vapor permeable liquid applied membrane does the trick. Scott describes this structural air barrier here:

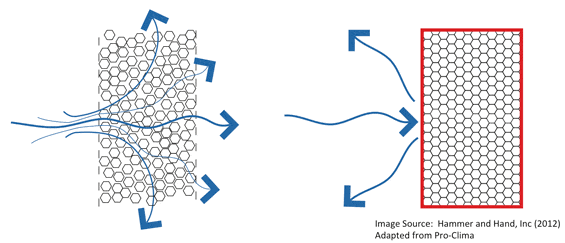

The air barrier prevents air from flowing through the wall and ensures that the cellulose cavity insulation performs at its highest level, much like a Gore-Tex jacket enables a sweater underneath to warm your body, shielded from air penetration and the moisture it carries.

The air barrier also keeps out wind-driven rain, protects sheathing and framing from moisture, and, because it’s vapor permeable, allows the wall assembly to dry out from the inside in the unlikely event that moisture intrudes to the interior portion of the wall assembly.

This air barrier is wrapped by the home’s winter overcoat, a 6”-thick exterior layer of foil faced polyiso foam (R-36) that brings the insulative value of the overall wall assembly to nearly R-60. The three layers of 2-inch foam nest into a superstructure of Z-joists that staggers each layer’s seams. Vapor permeable tape seals exterior seams. This continuous overcoat is key to the wall assembly’s performance and durability. In addition to allowing very little heat loss, it also protects the structural air barrier by keeping it warm and dry. The warm band of yellow that encompasses the air barrier layer in the diagram below comes thanks to these three layers of polyiso foam (coinciding roughly with the quite-cold purple, the cold blues, and the merely-cool green below).

Finally, the green building is wrapped with a rain screen system built of FSC-certified cedar siding held one inch off the polyiso foam by FSC 1×4 battens. The airflow that this rain screen cavity facilitates across the face of the wall assembly provides constant drying and drainage, ensuring longterm performance and durability. Scott describes the system here:

So we’ve built this great wall assembly, but every window opening on the house represents a big hole poked through. We know that the hull of our ship can’t have leaks, so window preparation and installation are mission critical to creating a high performance wall assembly. Our simple approach connects the home’s high performance wall with its high performance windows while avoiding thermal bridges, water intrusion and air leaks. See Scott discuss window preparation here:

And watch Scott’s demonstration of window installation here:

Moisture management is the watchword when creating a high performance building envelope like the one at Karuna. By controlling heat and air you control moisture (hence, the Heat Air Moisture, or HAM, focus of building performance experts), so we designed every layer in the wall assembly at Karuna to manage these three variables. But we also created an assembly with excellent drying potential so that if something unforeseen happens and moisture somehow enters the system, the wall assembly will be able to handle it. This ensures building envelope durability, the most fundamental definition of building sustainability.

See an annotated photo tour of the assembly’s layers: