Our “Evolution of Enclosure” exhibit at AIA Portland (open through September 10) examines the role that buildings – especially building enclosures – can play in helping to diffuse climate change. As examples, the exhibit draws on four projects built by Hammer & Hand: Karuna House designed by Holst Architecture; Pumpkin Ridge Passive House and Glasswood Commercial Retrofit, both designed by Scott | Edwards Architecture; and Madrona Passsive House designed by SHED Architecture & Design.

The exhibit itself includes a set of four beautiful full scale cross sections, built by Hammer & Hand’s Jason Woods, of the high performance wall assemblies for these four projects to achieve the Passive House performance. Drop by AIA Portland to check them out!

Each of these wall cross sections is accompanied by a series of illustrations, created for us by Ryan Sullivan of Paste in Place, explaining how each manages for heat, air, and moisture. In a series of four posts we plan to share these illustrations and the analysis embedded within in them. This week, Karuna House!

Karuna House

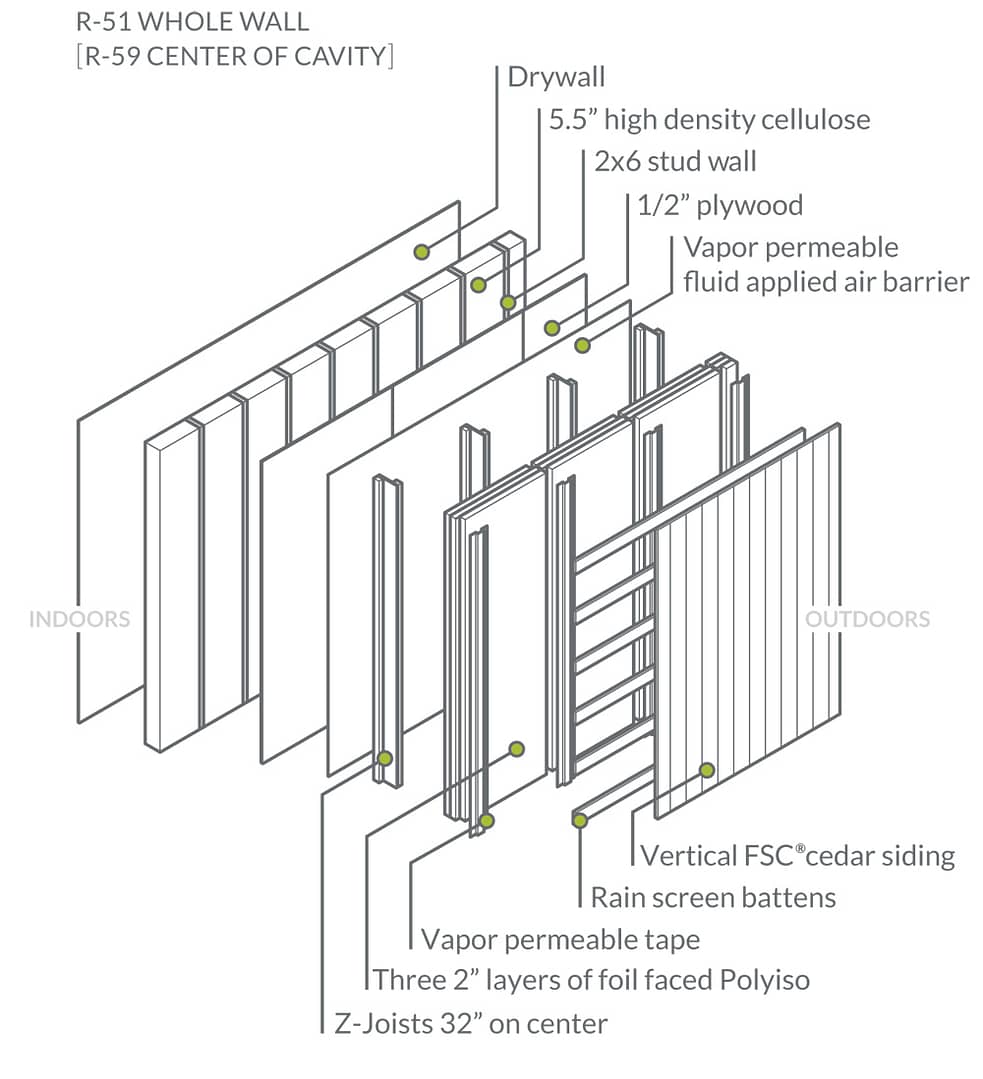

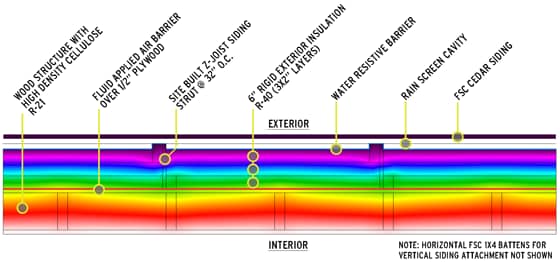

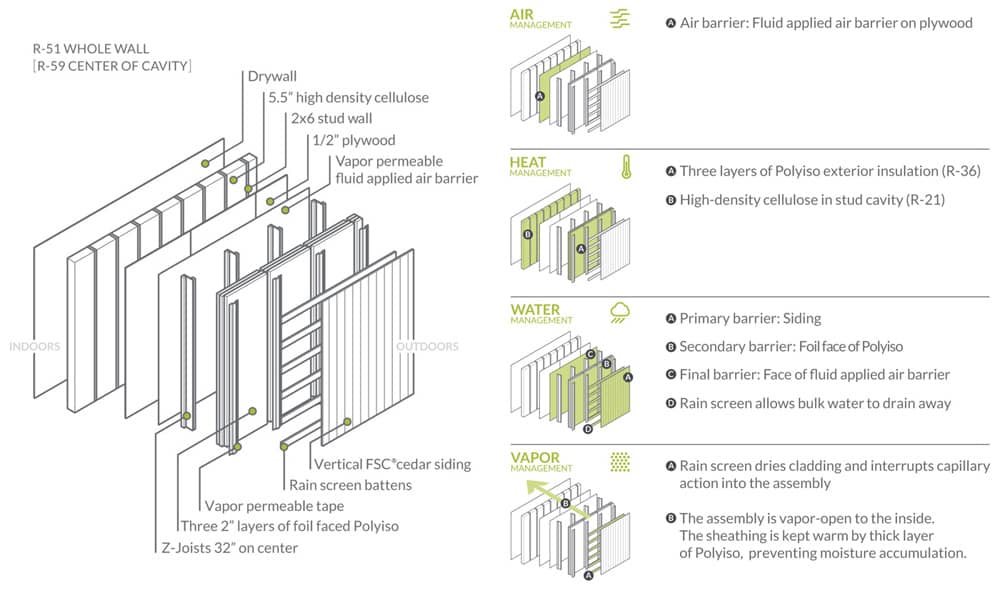

At Karuna House, the client and designers determined the form of the building first and the strategy to bring that design to high performance levels was overlayed second. So the wall assembly had to be especially thermally resistant to allow for the form’s articulations and increased surface area. The key challenge was to do this while not making the wall extremely thick.

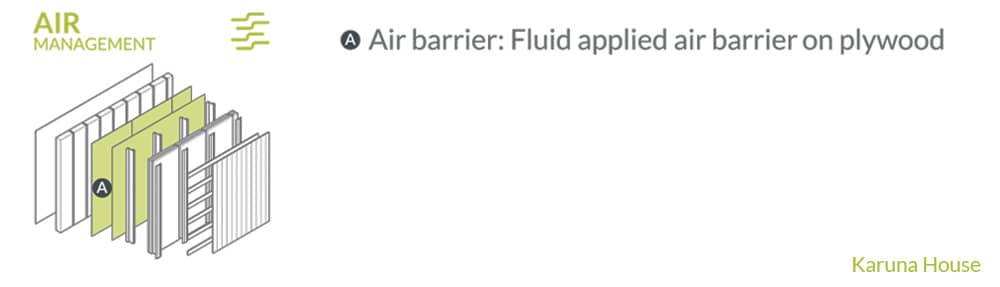

The air barrier for the Karuna House wall assembly is a fluid applied, vapor-open membrane manufactured by Prosocco.

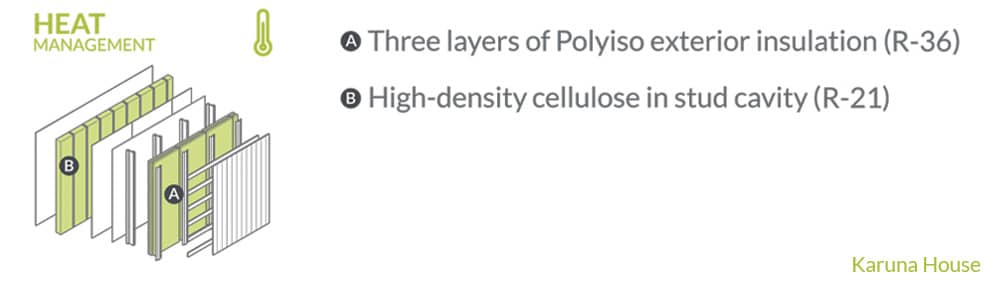

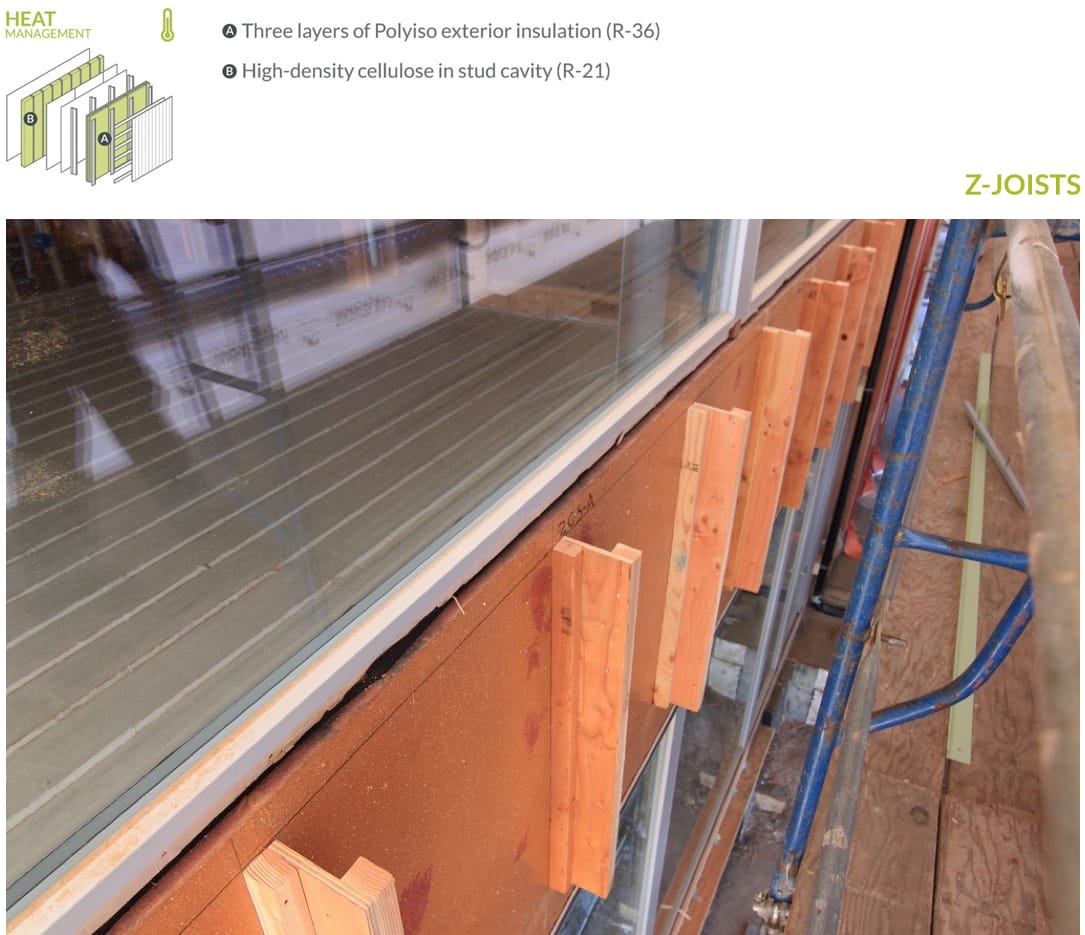

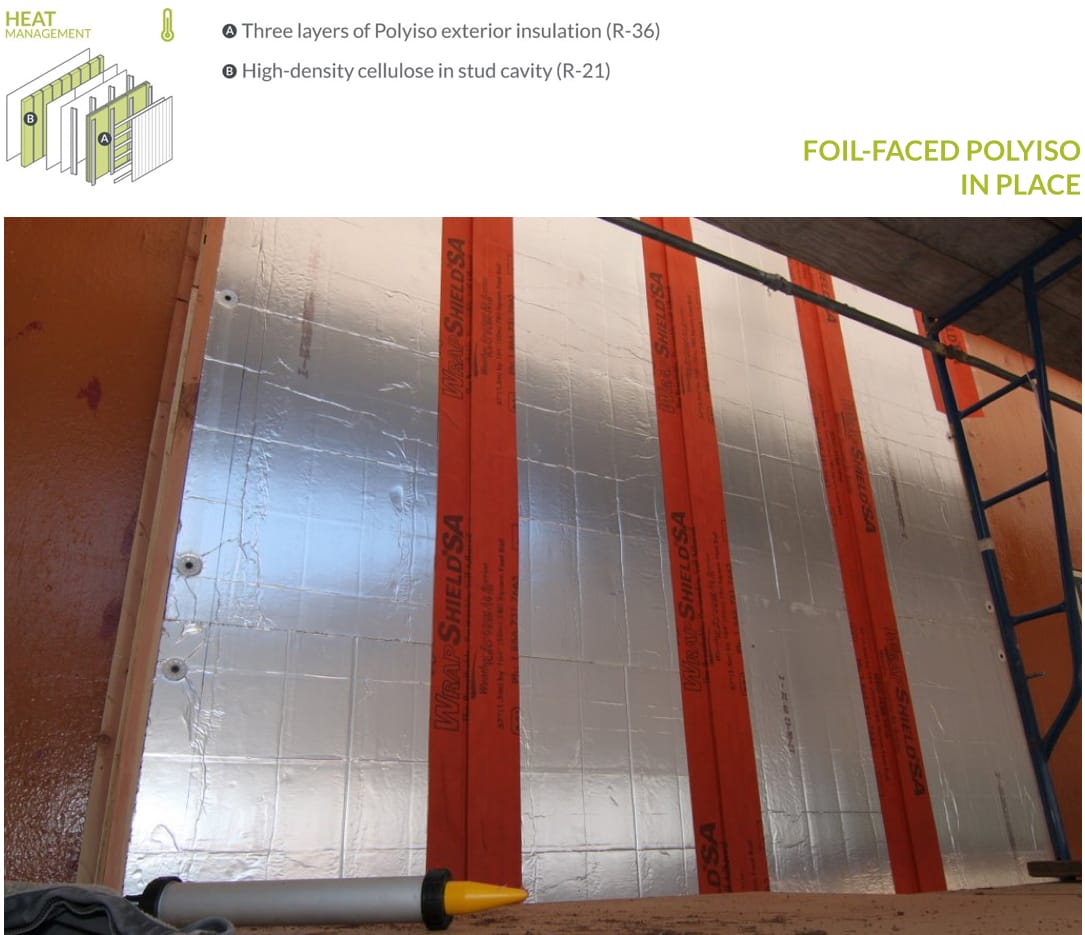

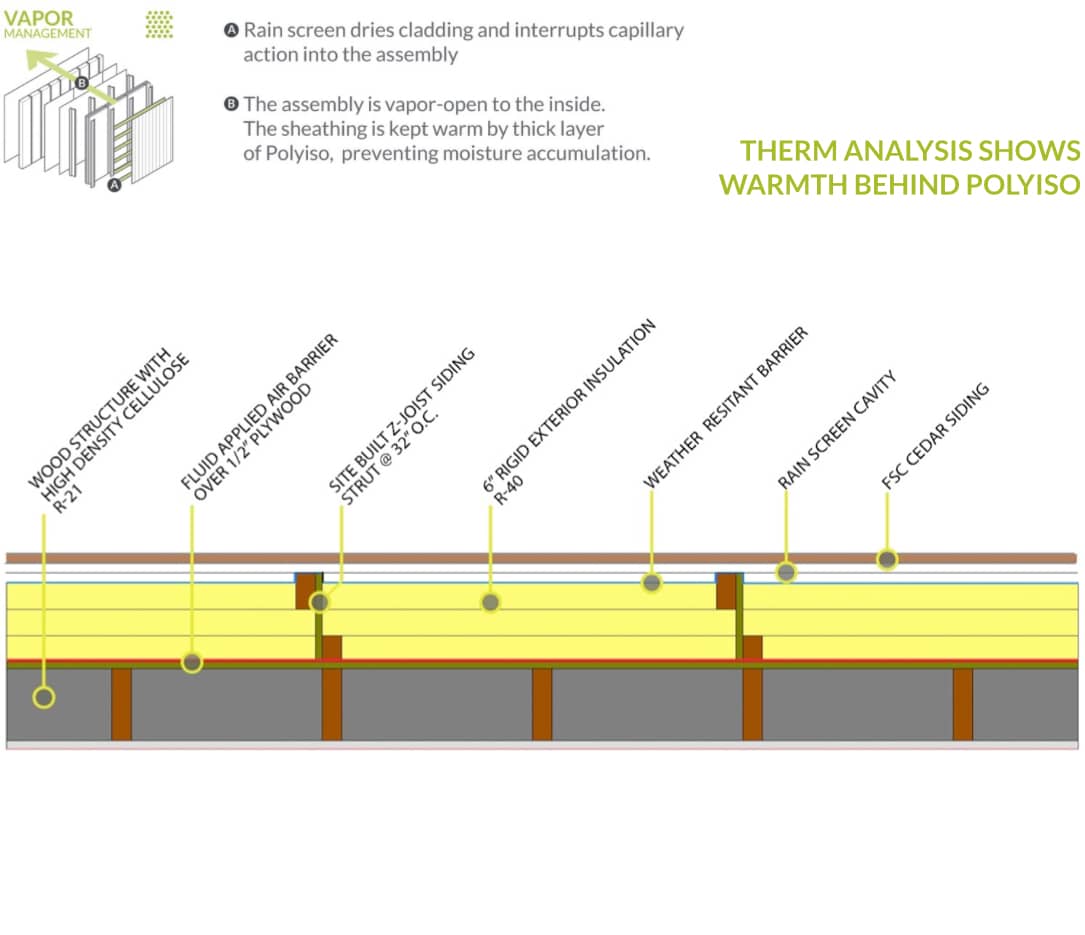

The assembly’s high R-59 insulative value (center of cavity, including gypsum, plywood, and air films) is provided by a 5.5” layer of high density cellulose (R-21) and three 2” layers of foil faced polyisocyanurate insulation (R-36) with seams offset by the z-girts that hold the layers in place.

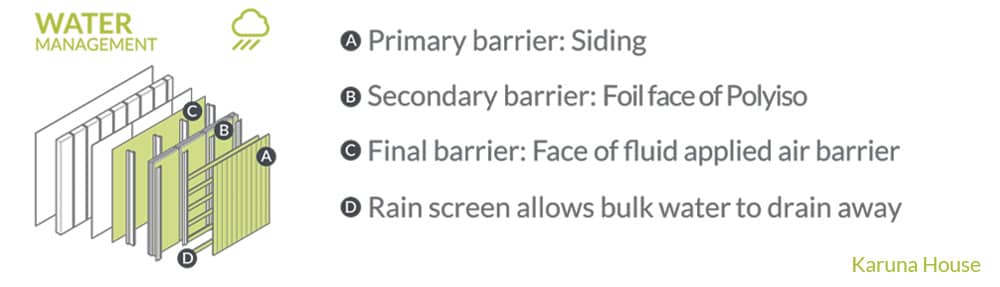

The first line of defense for bulk water management is Karuna House’s siding and the ventilated rainscreen cavity behind that siding that allows water to drain harmlessly away. The second barrier is the foil face of the Polyiso insulation. And if any water were to penetrate beyond that, the final barrier is the fluid applied, vapor-open air barrier mentioned above.

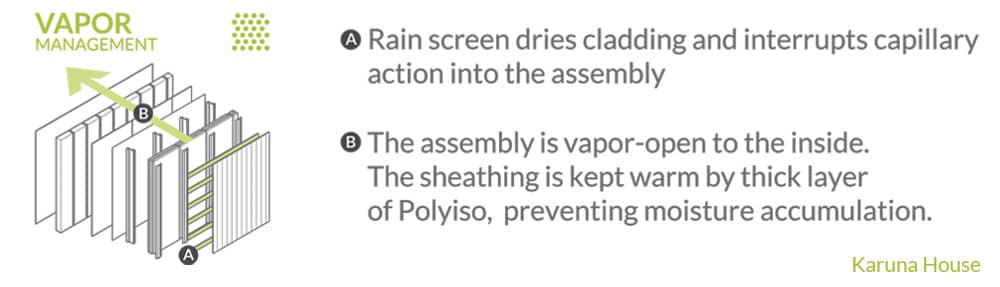

Starting just inboard of the innermost layer of foil faced Polyiso (the foil is a vapor barrier), the assembly is vapor open to the inside, but not the outside.

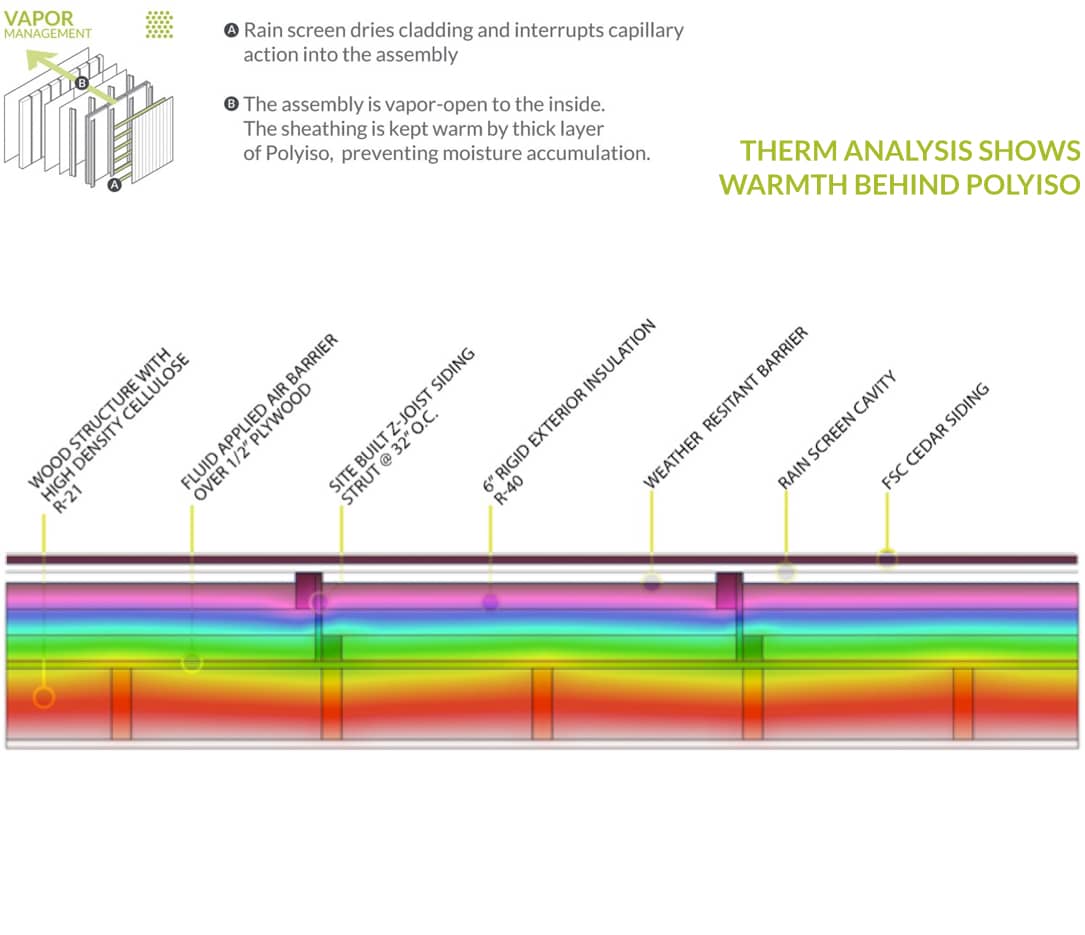

This strategy works because the Polyiso keeps the structural sheathing so warm and protected, as shown in this THERM diagram. Any water that finds it way between the Polyiso and the fluid-applied air barrier gets warm, becomes vapor, and then transfers harmlessly inside through the vapor-open side of the assembly.

See an annotated photo tour of the assembly’s layers:

Check out the other posts in this high performance wall assembly series: