THERMAL BRIDGE-FREE CONSTRUCTION

A thermal bridge is any component in a building assembly that “bridges” inside and outside thermally, allowing heat and cool to short circuit the thermal resistance built into that building assembly. They hide in plain sight: in the form of wood framing, or a junction between wall and concrete foundation, a balcony slab, or even a single metal tie penetrating a wall. In each case they interrupt the insulation layer with a material that conducts heat, providing a direct line for the transfer of thermal energy across the building envelope.

Thermal bridges can short-circuit the best-laid plans for building envelopes. They rob buildings of comfort and efficiency. And because their cold influence can introduce condensation into the inner recesses of assemblies, thermal bridges can cause mold, rot, and building failure.

While thermal bridges don’t have a huge effect on poorly insulated buildings, as buildings get more and more insulated, the weak link of thermal bridging becomes more pronounced, as does the impact on building performance, comfort, and durability.

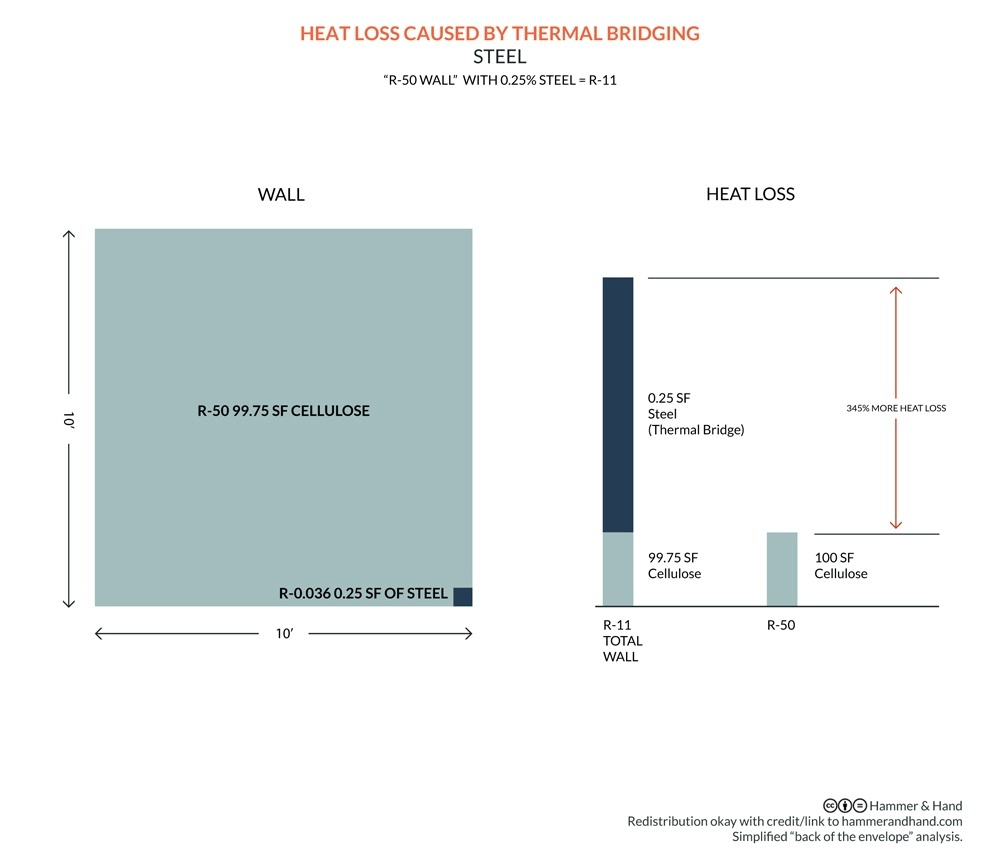

The best insulation in the world won’t get you anywhere if you ignore thermal bridges. Thermal energy seeks the path of least resistance, and common building elements like concrete slabs and steel plates can serve as a virtual autobahn for escaping energy, an easy detour around even the thickest of insulation.

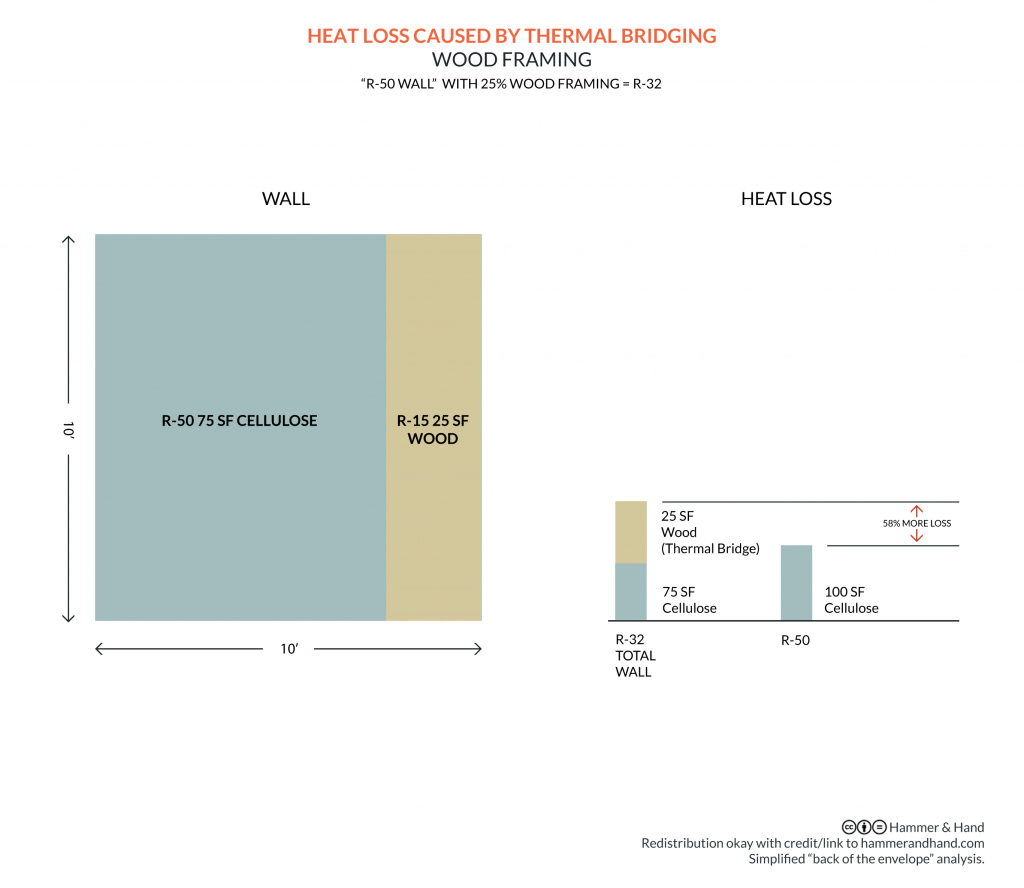

A common mistake in the building industry is to assume that a wall’s thermal resistance is equal to that of the insulation it contains. Consider a super-insulated example: a 15” thick wall full of cellulose insulation. 15” of cellulose insulation has an insulative value of R-50, so by definition the wall must be R-50, too. Right? No. We have to look at the thermal resistance of the wall in assembly. How is the wall constructed? Do any of its components reduce thermal resistance or create thermal bridges?

A standard wood frame wall, for instance, contains roughly 25% wood studs, leaving 75% for insulation cavity. And though wood isn’t particularly conductive, each of those studs is a thermal bridge, particularly when compared to R-50 insulation. The back-of-the-envelope analysis below, prepared by Skylar Swinford, shows that the wood in a wood frame/cellulose insulation assembly drops the insulative value from R-50 to R-32, allowing 58% more heat loss than an R-50 cellulose monolith. (Note that the calcs below do not include the slight insulative value of surface air films.)

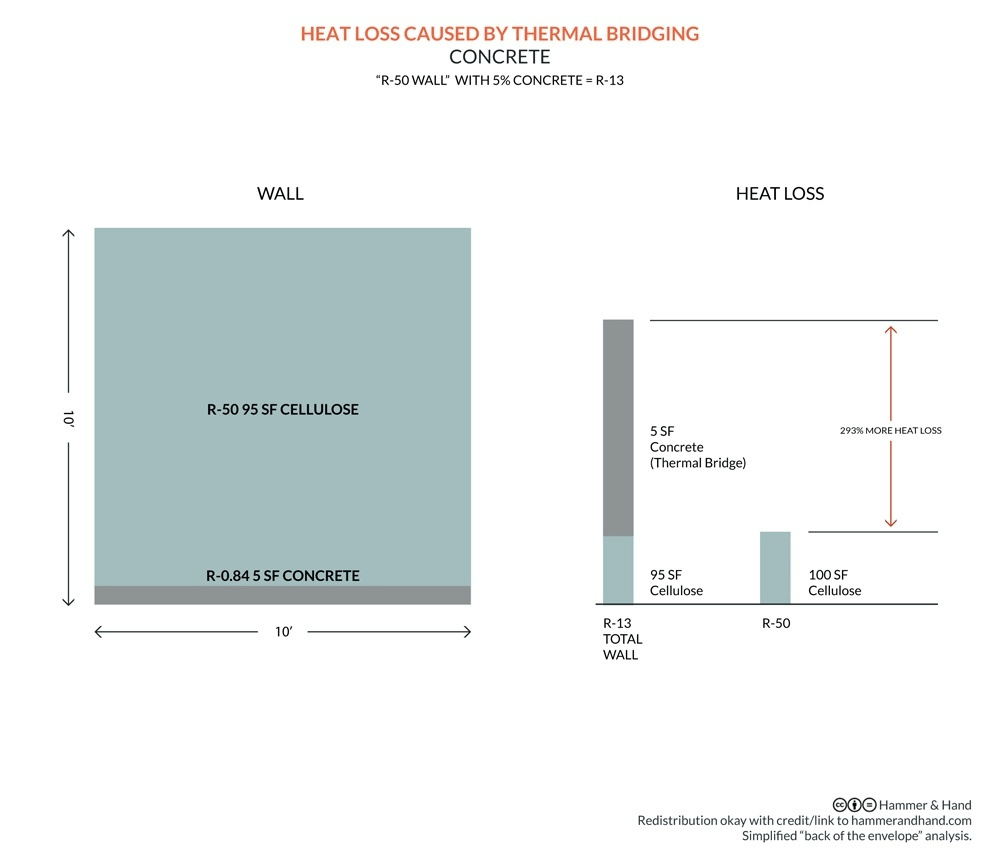

If we move to a more conductive material, like concrete, then the impact of thermal bridging becomes more dramatic. A 6” concrete beam cutting across a 10’x10’ wall of R-50 cellulose will drop that assembly to just R-13. The concrete makes up just 5% of the assembly but leads to 293% more heat loss.

If we move to a more conductive material, like concrete, then the impact of thermal bridging becomes more dramatic. A 6” concrete beam cutting across a 10’x10’ wall of R-50 cellulose will drop that assembly to just R-13. The concrete makes up just 5% of the assembly but leads to 293% more heat loss.

So, mind those thermal bridges because they can wreak havoc with your building’s performance and durability.

We start by carefully detailing buildings to minimize thermal bridging in the first place, through advanced framing, carefully detailing junctions, no uninsulated concrete or metal penetrations of the thermal envelope, and more. We then wrap our high performance buildings with continuous insulation to break any remaining bridges.