Components

Rain Screen

Despite their name, rain screens’ main claim to fame is not the screening of rain. That’s what siding does. In our wet climate, the most important function of a rain screen – more precisely, a ventilated rain screen – is to increase the drying capacity of wall assemblies.

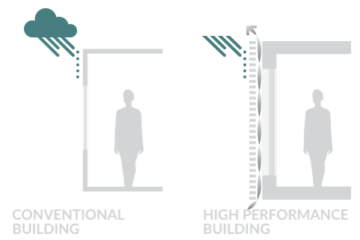

When we build a high performance wall we are, by definition, decreasing the amount of air and heat energy that crosses that assembly. So, all things equal, we are decreasing the drying potential of that wall. Knowing this, we are careful to design the assembly to manage vapor and moisture and avoid condensation. We conduct thorough hygrothermal analysis with powerful modeling software to simulate how moisture and temperature will interact over the seasons year after year. Still, to ensure resiliency we want to increase the drying capacity of our high performance walls.

Enter the ventilated cavity of the rain screen.

Rain screens consist of three layers: the cladding, the gap, and the water-resistive barrier (WRB). The cladding’s job is to protect the WRB from the elements, such as rain and wind. The WRB’s job is to protect the rest of the building from the elements, especially wind-driven rain.

When you add a gap between the cladding and the WRB you’ve created a rain screen. All it takes is a simple batten system. But the simplicity of rain screens belies their power, because that cavity, when ventilated at top and bottom, is key to the durability of thermally resistant buildings in our damp, maritime Pacific NW climate.

Built properly, this cavity will:

- Introduce a capillary break between the cladding and the WRB, short circuiting the wicking of moisture between those two layers.

- Create a drainage plane between the two layers, allowing any bulk water that gets through the cladding to drain away harmlessly.

- Generate an air-moving stack effect (when ventilated at top and bottom) that creates hundreds of air changes per hour between the cladding and the WRB.

(Note: many rain screens built in drier regions outside the maritime Pacific NW are not ventilated and therefore only serve the capillary break and drainage plane functions.)

Ventilated rain screens dramatically increase drying capacity. All that air moving across the face of a vapor-open WRB acts like a big fan, drawing moisture out of the wall assembly. This drying effect is also great for the longevity of the cladding.

It turns out that the ventilated cavity is not new. The Romans knew about the virtues of ventilated wall cavities over 2,000 years ago. As we recently learned from Mark R. Morden, Associate Principal at WJE, Vitruvius wrote about them in his “Ten Books On Architecture.” Joe Lstiburek also cited Vitruvius recently in his “Vitruvius Does Veneers.”

“…if a wall is in a state of dampness all over, construct a second thin wall a little way from it…at a distance suited to the circumstances…with vents to the open air…when the wall is brought up to the top, leave air holes there. For if the moisture has no means of getting out by vents at the bottom and at the top, it will not fail to spread all over the new wall.” (Book VII, Chapter IV)

This video shows a real-world example of a ventilated rain screen:

See the rain screen chapter of our Best Practices Manual for details on how to construct one in the field.