Left to her own devices, Nature would turn buildings into mulch. Her primary tool for doing so is water, because water plus oxygen plus wood equals rot – at least in the mild temperatures of the Pacific NW – and rot means building failure: mulch.

The key to ensuring building durability is to keep building assemblies dry to prevent rot and to facilitate the drying of assemblies whenever they do get wet. This means managing bulk water (rain, mostly), airborne water vapor, vapor transmission at the molecular level (across assemblies from areas of high vapor concentrations to low vapor concentration), and condensation.

The old way of doing all this was to build walls full of air leaks, clad them well, put on a good roof, and blast the building with heat from a fireplace, boiler, or furnace throughout the winter. Even with this blast of internal heat, the leaky walls might accumulate moisture during the winter in our maritime NW climate, but they would dry out during the summer: all that air and heat passing through them did the trick. It was a resilient approach. Unfortunately it was also wasteful of energy, uncomfortable, and led to poor indoor air quality.

What’s the new way? How do high performance buildings ensure durability? A prerequisite is to execute the level of craft necessary to eliminate bulk water intrusion, of course. With that accomplished, the first priority of high performance building is airtight construction because by controlling the movement of air we also control the movement of moisture and heat. We know that one of the quickest ways to drive moisture into a wall is through an air leak. Warm interior air carries water vapor with it into the wall assembly, and if it hits a cold surface, that vapor can condense into liquid water and wreak havoc. Airtight construction stops air movement – and therefore the movement of airborne vapor – into building assemblies.

The next step in ensuring durability in high performance building is thermal bridge-free construction. Because thermal bridges (any building element that cuts across and bypasses a building’s insulation or “thermal envelope”) create cold penetrations through otherwise warm parts of building assemblies they can become focal points of condensation, moisture build-up, and rot. By eliminating or mitigating these thermal bridges, high performance building removes these condensation-inducing cold points in building assemblies.

With airtightness and thermal bridge-free detailing dialed in, we then turn our attention to managing vapor drive, or the movement of vapor molecules from areas of high concentration to areas of low concentration. As we do this, we pay close attention to the dew point (a function of heat and humidity) to ensure that condensation doesn’t occur where it can do damage. To guide our work, we harness the power of thermal and hygrothermal modeling software, charting the behavior of moisture and heat through assemblies over time. Generally speaking, in our maritime NW climate, our hygrothermal analysis leads to wall assemblies that are “vapor open” in both directions, into and out of the building. If, for some reason, moisture concentrations build up, that moisture can then readily escape the assembly.

See the Pumpkin Ridge Passive House wall assembly and Madrona Passive House wall assembly for two examples of walls that are vapor-open in the both directions.

To increase the drying capacity of high performance wall assemblies, we add ventilated rain screens. The ventilated cavity behind the cladding facilitates lots of airflow (measured in the tens to hundreds of air changes per hour) across the face of the wall assembly proper, dramatically increasing the wall’s drying capacity and, therefore, resiliency. This air movement also allows the cladding itself to dry thoroughly, increasing its lifespan and reducing the maintenance requirements of the building exterior.

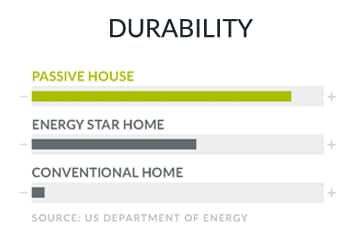

This high performance approach to building durability is informed by decades of building science insight. By their very nature, high performance building envelopes limit the flow of heat across them, which, all things equal, would inhibit their ability to dry out. But by stopping airborne vapor intrusion, eliminating condensation-inducing thermal bridges, managing vapor drive, and augmenting drying capacity with ventilated rain screens, the durability of high performance buildings exceeds that of the old, leaky approach to construction. This is why the US Department of Energy rates Passive House buildings as so much more durable than conventional ones.

Nature’s desire to turn our buildings into mulch is foiled by the holistic management of air, moisture, and heat by high performance buildings.