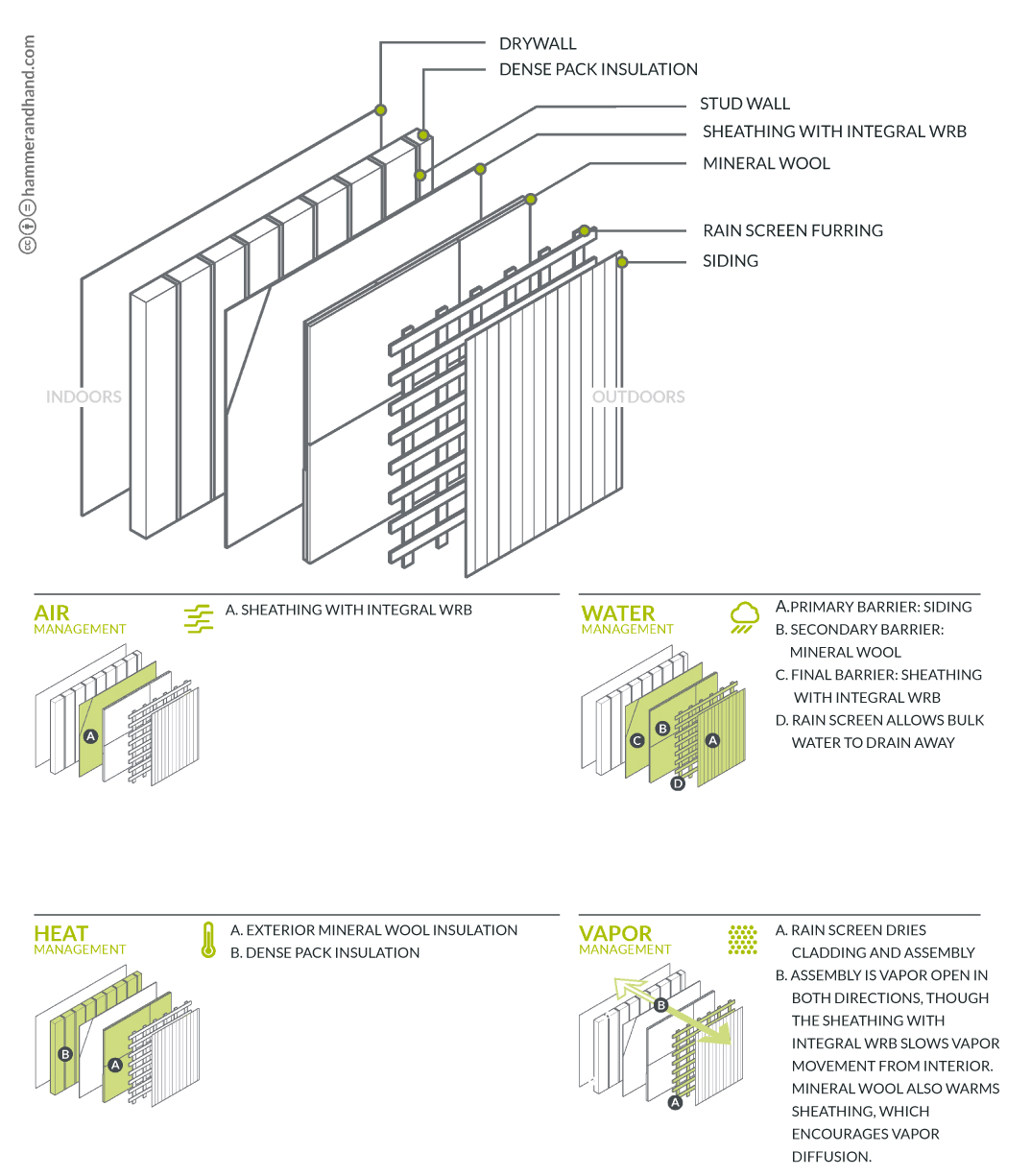

5.5 Wall Assembly Example

A. DENSE PACK INSULATION

B. SHEATHING WITH INTEGRAL WRB

C. JOINT & SEAM FILLER

D. MINERAL WOOL INSULATION

E. FLUID APPLIED SYSTEM AT PUNCHED OPENING

F. CEDAR SIDING (VERTICAL)

G. SILL PAN FLASHING

H. 2-WAY RAIN SCREEN FURRING

I. WINDOW BUCK

J. FRAMED STUD WALL

K. HEAD FLASHINGNote: Metal flashings not to return back to sheathing.

B. SHEATHING WITH INTEGRAL WRB

C. JOINT & SEAM FILLER

D. MINERAL WOOL INSULATION

E. FLUID APPLIED SYSTEM AT PUNCHED OPENING

F. CEDAR SIDING (VERTICAL)

G. SILL PAN FLASHING

H. 2-WAY RAIN SCREEN FURRING

I. WINDOW BUCK

J. FRAMED STUD WALL

K. HEAD FLASHINGNote: Metal flashings not to return back to sheathing.

This example combines an exterior layer of mineral wool insulation, ZIP Sheathing as air barrier and water-resistive barrier, fluid-applied flashing at rough openings, and dense pack insulation (cellulose or fiberglass) in an interior stud wall for a super insulated, vapor open, and resilient high performance wall assembly. The diagrams below show how the assembly manages air, heat, water, and vapor.