Usually when you think about lighting and energy efficiency you think about florescent or LED bulbs, or natural lighting.

But you may be missing a major energy efficiency issue in lighting: air infiltration. This energy thief preys upon recessed lighting – can lights, high hats or pot lights – a highly attractive lighting type for homeowners and builders alike. They are simple, inexpensive, easy to install, and very clean looking. But many of these lights allow lots of energy loss and make home performance suffer.

Not all recessed lighting is created equal. The cheapest can lights available are littered with holes. Cut a hole in your ceiling and pop one of those in, and you have effectively left a 10 square-inch hole in your ceiling air barrier. As you heat or cool your home, conditioned air literally gushes out through these openings. We see this time and time again on our Home Performance Assessments, and will test your fixtures to see just how leaky they are. Sometimes they are not, usually, they are.

Luckily, there are some great fixes available. You may have heard about “IC-rated” recessed fixtures. This means that they are rated for “Insulation Contact”. While these are better than non-IC rated fixtures, because your insulation can be continuous over the top of them, they are not necessarily air tight. And air tightness is the goal – to have a nice seal at the fixture that minimizes the amount of air  that can leak through and around the fixture. For new construction, you should look for an “ICAT-rated” fixture. ICAT stands for “Insulation Contact Air Tight”. (I think you get the idea.)

that can leak through and around the fixture. For new construction, you should look for an “ICAT-rated” fixture. ICAT stands for “Insulation Contact Air Tight”. (I think you get the idea.)

For retrofitting existing non-IC-rated or IC (non air-tight) recessed lighting, my favorite option is an LED light insert, which is made specifically for this purpose. The color rendering is beautiful, they’re dimmable down to 25% of full power, and they’re quick to install. These LED light inserts have a sealed housing, and with a couple of quick tweaks on your existing fixture they fit right in. Add a bead of caulk and you’ve got a great seal. In addition, they use 1/5 the energy of a comparable lumen incandescent.

A mid-range solution is to use a florescent product like the Powerlux can light insert. This product adapts your existing can light to a pin style CFL (compact florescent) and contains the ballast in a thick trim housing that sets beneath the ceiling surface. Because the ballast is placed in a location that is cooler, the light can operate at optimal efficiency and the ballast enjoys extended life.

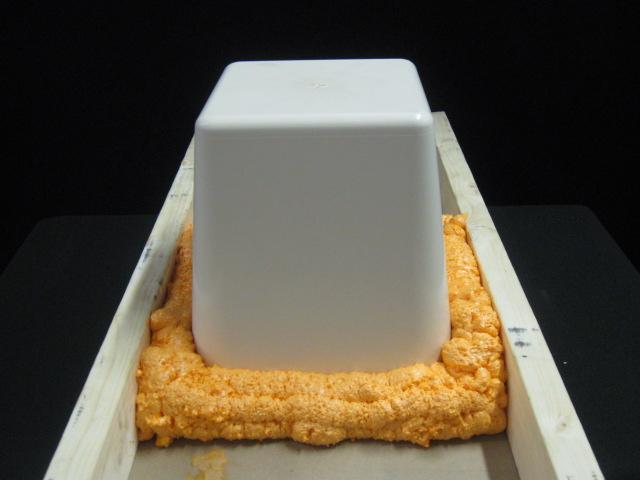

A less expensive option is to either build a drywall box or install preformed, fire rated “pots” that go over your existing lighting up in the attic. We seal them to the ceiling with foam. With this fix, it’s important to u se CFL since they produce less heat and use about ¼ of the energy than a comparable lumen incandescent.

se CFL since they produce less heat and use about ¼ of the energy than a comparable lumen incandescent.

Regardless of the solution you choose, it all goes back to limiting air infiltration in your home. We measure this level of leakiness (or tightness, depending on whether you’re a glass half-full or half-empty kind of person) with a blower door test during our Home Performance Assessments. Limiting air infiltration in your building envelope is critically important. Why? Big energy savings and improved comfort in your house.

– Jacob, Building Analyst