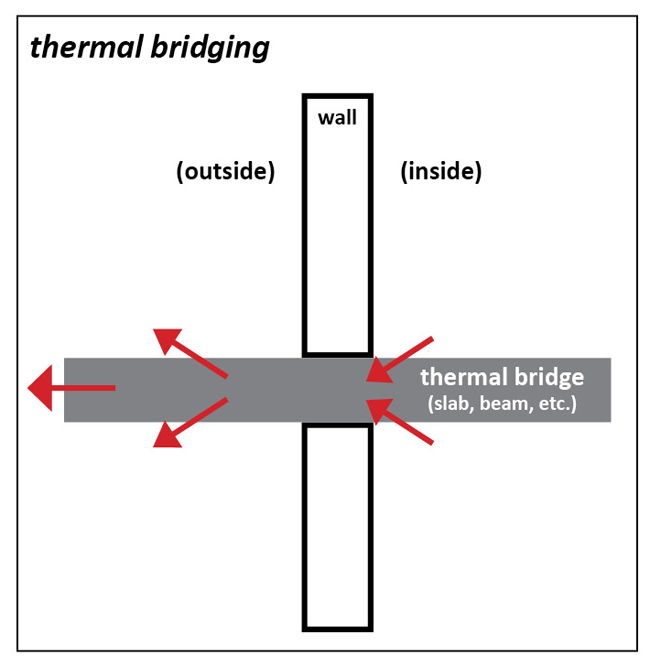

A look at thermal bridges and their effect on building performance.

The Thermal Bridge: Stealthy Nemesis of Energy Efficiency

Thermal bridges are sneaky. For starters, their name hides their nefarious nature, implying some kind of connection to warmth and coziness. The opposite is true, and the alias “cold bridges” is more telling, if less used.

Thermal bridges are penetrations in a building’s insulation layer, or “thermal envelope,” that allow heat to escape and cold to intrude. (In the winter that is – the reverse happens in summer.) They hide in plain sight, in the form of wood framing, or a junction between wall and concrete foundation, a balcony slab, or even a single metal tie penetrating a wall. In each case they interrupt the insulation layer with a material that conducts heat, providing a direct line for the transfer of thermal energy across the building envelope.

Thermal bridges can short-circuit the best-laid plans for insulation. They rob buildings of comfort and efficiency. And because their cold influence can introduce condensation into the inner recesses of wall assemblies, thermal bridges can wreak havoc.

Thermal bridges can short-circuit the best-laid plans for insulation. They rob buildings of comfort and efficiency. And because their cold influence can introduce condensation into the inner recesses of wall assemblies, thermal bridges can wreak havoc.

Granted, for poorly-insulated buildings, thermal bridges don’t have a huge effect. But as a building gets more and more insulated, their impact on building performance, comfort and durability rises dramatically. That’s why thermal bridges are verboten in Passive House construction.

H&H’s Skylar Swinford ran a series of energy modeling calculations to illustrate the relative impact of wood, concrete and metal thermal bridging on the thermal performance of a hypothetical wall assembly. For his simulations he started with a 10’ x 10’ wall section, insulated with a thick layer of dense-packed cellulose with a very high insulative capacity of R-50.

In the first simulation he assumed that the insulation was interrupted in regular intervals by conventional wood framing. So 75% of the 10’ x 10’ sectioned remained as cellulose insulation and 25% became framing lumber. While you don’t think of wood as particularly conductive of heat or cold, it is much more so than R-50 insulation. The energy transferred through these wood thermal bridges reduced the performance of the 10’ x 10’ wall by 36%, to an R-value of 32.

Next Skylar looked at what would happen to the R-50 wall if a 1’ wide section of concrete were introduced, roughly analogous to a junction between an exterior wall and concrete foundation wall, for example. In this simulation, 90% of the wall remained as cellulose insulation and 10% became concrete. This change robbed the wall of a whopping 86% in performance, for an R-value of just 7. Brrrr!

Finally, Skylar ran a simulation to see what would happen if the R-50 wall was penetrated by a single piece of steel, sized at just 3.75” x 3.75”. In this case, 99.9% of the wall remained as cellulose insulation and a tiny 0.1% became steel. Performance of the 10’ x 10’ wall plummeted by 58%! A single piece of steel brought R-value down from 50 to 21.

| Nature of Thermal Bridge | Impact on 10′ x 10′ Wall (R-50) |

|---|---|

| Wood Framing – 25% of Wall | 36% Reduction in Thermal Performance |

| Concrete – 10% of Wall | 86% Reduction in Thermal Performance |

| Steel – 0.1% of Wall | 58% Reduction in Thermal Performance |

The point of the exercise is this: the best insulation in the world won’t get you anywhere if you are ignoring thermal bridges. Thermal energy seeks the path of least resistance, and common building elements like concrete slabs and steel plates can serve as a virtual autobahn for escaping energy, an easy detour around the thickest insulation.

The answer? Thermal breaks.

If you want to conquer the thermal bridges in your existing house, for example, the quickest path may be to add a layer of continuous, monolithic insulation around its exterior to create one big thermal break. Rigid foam insulation or a Larsen truss system can do the trick.

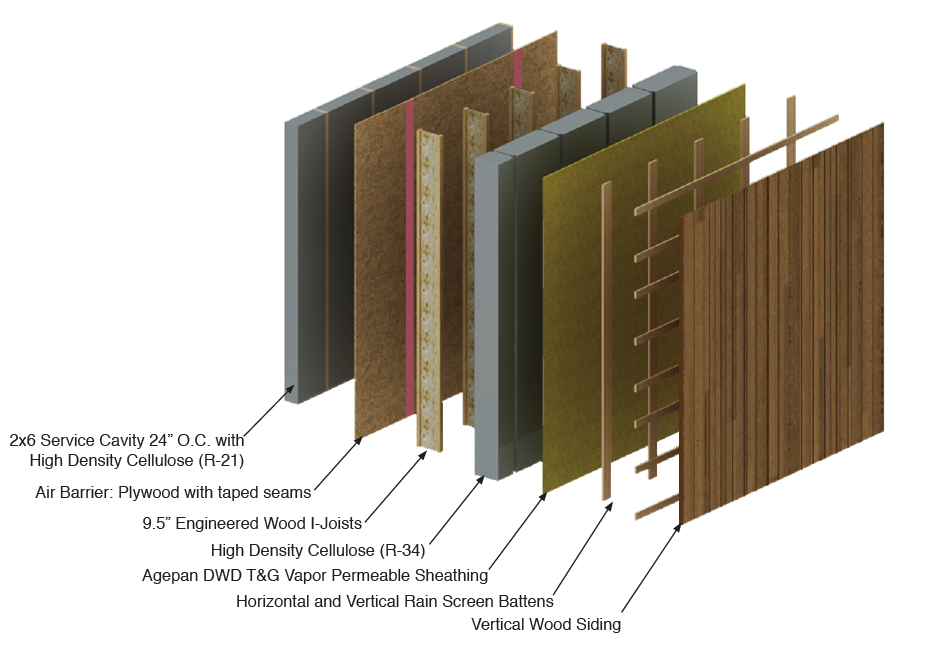

For new construction the approach is often two pronged. First, detail the building to minimize thermal bridging in the first place (through advanced framing, carefully detailed junctions, no un-insulated concrete or metal penetrations of the thermal envelope.) Then wrap it in continuous insulation.

Here’s a high performance example from a recent new home we built, the Pumpkin Ridge Passive House:

The details vary, but the basic approach remains constant. Break those thermal bridges if you care about performance.

– Zack (Connect with me at +ZacharySemke)

P.S. See this excellent video from Engineering.com on the subject.

Back to Field Notes