A home performance test-out helps homeowners understand what to expect.

Our own Greg Lasher recently conducted a home performance test-out of Patricia Marchetti’s beautiful home just off the Alameda Ridge. As owners of the EarthTechling, the largest green/sustainability publication headquartered in Oregon, Partricia and her husband Nino decided to get an energy retrofit to make their 1927 romantic revival home more comfortable.

“Owning an older home is a joy – but the house wasn’t good at holding heat in,” Patricia said.

A test-out performed in the Clean Energy Works Oregon program is a series of tests conducted by a contractor supervised by an independent Energy Assessor to verify that energy measures installed during an energy retrofit are effective and safe.

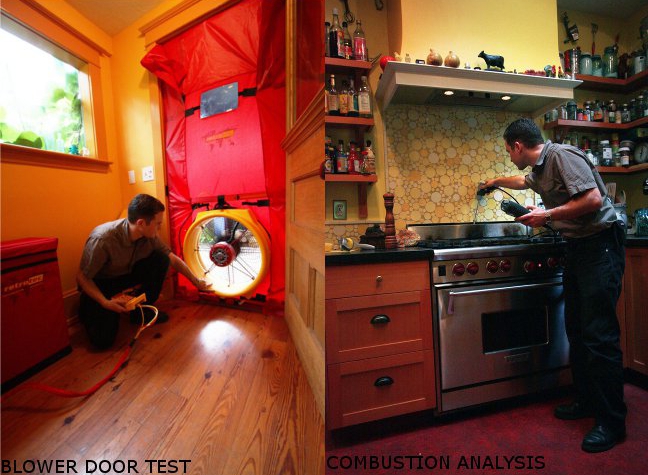

Test-outs provides homeowners with a clear before and after picture of their home’s efficiency by comparing data gathered during a test out with data gathered during an initial assessment. Every test-out is a little different because every home is unique, but most test outs feature three important assessments: the blower door test, the worst case pressurization test, and combustion analysis.

Before conducting the actual tests, Greg walked through the home and visibly inspected the energy measures installed during our energy retrofit, which included insulating the attic, garage, and a crawl space in the basement. Fiberglass insulation was replaced with spray foam (pictured below).

After inspecting the energy measures Greg moved on to the blower door test. A blower door is essentially a powerful exhaust fan that is temporarily sealed into an exterior door frame. By comparing how hard the fan had to work to suck air through the home to a standardized pressure, Greg determined that air sealing and insulation decreased air leakage by one-third.

Patricia and her family have noticed the difference, “The house is much more comfortable than before. It really is amazing how a little insulation can go a long way.”

After breaking down the blower door Greg moved on to the combustion analysis. This test checks combustion devices to make sure that they don’t leak harmful gases into the home. This test is particularly important during a test-out because harmful gases have fewer places to escape to post-retrofit.

While holding the combustion analyzer over the gas range, Greg explained why installing insulation can make such a big difference in energy efficiency.

“Old homes were designed to be drafty for better air quality and because energy was so inexpensive. But we also know that insulation performs better in a tighter home. Since energy prices are high and going higher we need our insulation to work. The sweet spot that we take homes to is a mechanically ventilated home that is much tighter than the original. We add substantial insulation and the home is more comfortable and safe.”

After determining that levels from the range were within safe limits, Greg performed a worst case depressurization test. This is a fancy name for making sure that the furnace and hot water heater aren’t backdrafting. Backdrafting can occur when a combination of exhaust fans, range hoods, and door closures pull combustion gases into the living space.

A test-out is arguably the most satisfying part of any energy retrofit because it validates what the homeowner has known anecdotally for a couple of days or weeks – that their house is more comfortable, safe, and efficient.

– Cody

Back to Field Notes