Passive House modeling tools can eliminate a key LEED blind spot.

The Passive House building standard wears blinders. Its sole laser-like focus is on building energy performance and durability.

So most Passive House practitioners recognize that broader sustainable construction approaches like LEED, are naturally complementary. Passive House brings depth, promising revolutionary reductions in the carbon footprint of our built environment. LEED brings breadth, addressing environmental concerns like toxicity, renewable materials, water conservation, stormwater management, waste reduction, access to alternative transportation and much more.

To truly build “green,” we understand that we need both depth and breadth.

The Karuna House, a project pursued by the client as a case study of green building and green building certifications, certainly bore this out. (Karuna is the first building in the world to achieve the trifecta of LEED, Passive House and Minergie-P-ECO certification.) The broad green mandates of both LEED and the “ECO” portion of the Swiss certification Minergie-P-ECO ensured that the Karuna project team look well beyond energy performance in its definition of sustainable construction.

But the Karuna House also proved how powerful Passive House’s advanced understanding of building performance can be for LEED practitioners and their projects. Because just as Passive House is “blind” to broader sustainability issues, LEED has its own blind spot: it can’t see thermal bridges, at least not without help. Thermal bridges are elements of a building (steel beams, building junctions, window-wall interfaces, etc.) that allow heat energy to escape across the building envelope. And while they may sound wonkish and technical, thermal bridges demand respect: they are anathema to high performance building, providing an escape route for heat (or cool) to circumvent super-insulated assemblies and for moisture to penetrate walls and wreak moldy havoc. Check out this Engineering.com video, “2 R’s Won’t Make Your U”:

In low-load building, where efficiencies are high and tolerances are low, thermal bridges have an outsized impact on both building performance and durability. Seemingly minor elements, like a steel plate, can put a real drag on the performance. J. D’aloisio, author of the “Structural Engineer’s Pledge to Improve Building Envelopes,” says this in his article “My Journey to the Thermal Bridge”:

“… steel conducts heat about 1200 times better than expanded polystyrene (EPS) rigid insulation. This means that if the EPS insulation in an exterior building wall is “bridged” by a steel plate across an area which comprises just one tenth of one percent of the wall’s total area, more heat can flow through the steel plate than the entire rest of the wall!”

At the Karuna House we discovered some bad news for LEED practitioners: the tools for determining building energy performance for LEED projects – the HERS Index as modeled by REM/Rate for residential projects, and eQUEST for commercial projects – generally ignore thermal bridges. The closest that REM/Rate comes to recognizing thermal bridges is to account for the energy loss transmitted through framing. In theory, your building’s envelope could be riddled with thermal bridges both obvious (steel beams protruding through walls) and obscure (poorly detailed foundation-to-wall transitions) and perform just as well in LEED’s eyes as a thermal bridge-free building. The reality, of course, would be much different, full of disappointing surprises for one (wasteful energy performance, mold, and building durability problems) and high performance contentment for the other. We could have built a Karuna House full of thermal bridges and it still could have achieved LEED Platinum status. But it would have failed Passive House and Minergie-P certifications miserably.

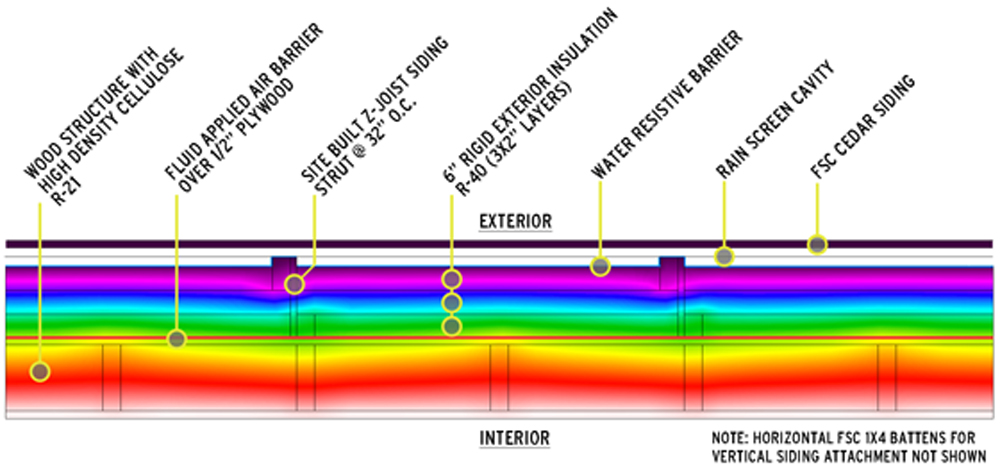

THERM Analysis of Thermal Bridge-Free Wall at Karuna House

Chicago’s Aqua Tower (certified LEED-NC) is a beautiful, high design example of LEED’s disconnect around thermal bridging. Joseph Lstiburek of Building Science Corporation writes in his article about the project, “Thermal Bridges Redux”:

“It is a beautiful building. Quite stunning actually. It is an embodiment of everything that is right and wrong with architecture. An orgy of glass and concrete. It is a thermodynamic obscenity while it takes your breath away. An 82-story heat exchanger in the heart of Chicago.”

Check out the article for some stunning infrared photography of the building, as well as his prescriptions.

The good news for LEED practitioners (and therefore for the rest of us, given what a force LEED is in the green building world) is that modeling tools borrowed from Passive House like the Passive House Planning Package (PHPP) and WUFI-Passive understand and address thermal bridges and can be plugged into the LEED process in a straightforward way. There’s a clear pathway – one that we used at Karuna – for LEED project teams to understand, quantify, and reduce thermal bridging, and therefore deliver on promised building performance.

Thanks to work done by Passive House Institute US and RESNET in creating the PHIUS+ certification, the U-value assembly data from PHPP that includes robust analysis of potential thermal bridges can now be entered into the backend of REM/Rate, allowing the software to incorporate vital thermal bridging data into the HERS Index score of the building. LEED certifications based on these enhanced HERS Index scores are no longer blind to performance-sapping thermal bridges.

An added bonus of getting tools like PHPP and WUFI-Passive included in the design process for LEED projects is that they are optimization tools, not just verification tools like REM/Rate. PHPP and WUFI-Passive can be used to analyze hundreds of different design configurations to determine optimal balance of efficiency, cost, and other design goals. Especially in budget-conscious high performance building, this ability for “parametric analysis,” or simultaneous testing of many design parameters, is mission critical. And the power of PHPP and WUFI-Passive are available to LEED practitioners regardless of whether they choose to pursue Passive House levels of performance.

Because Karuna’s purpose is to provide lessons for green builders, I’ll close this post with a few findings from the project that we think are relevant to LEED professionals, Passive House designers and builders, and the green building community as a whole:

- Not only are the broad scope of LEED and the singular focus of Passive House complementary, a paired approach is actually vital in achieving a truly “green” project. The Swiss Minergie-P-ECO designation recognizes this, with its “P” roughly equivalent to Passive House and its “ECO” similar to LEED.

- Effective energy modeling is vitally important in the design process of high performance building and tools borrowed from Passive House, like the Passive House Planning Package (PHPP) and WUFI-Passive, can help LEED projects eliminate the thermal bridge blind spot.

- As code bodies reach for increasing levels of building energy efficiency, the success of future performance-based code will depend on the same comprehensive energy modeling borrowed from Passive House that LEED projects can benefit from.

- Our big, collective goal – averting catastrophic levels of climate change through meaningful reductions in building greenhouse gas emissions (as called for by the 2030 Challenge) – therefore depends on better modeling that takes things like thermal bridges into account. Fortunately those tools are readily available, and improving in accuracy and ease of use.

– Zack (Connect with me at +ZacharySemke)

Further reading:

“BSI-059: Slab Happy”

The Karuna House Foundation System

Pumpkin Ridge Foundation System