Bright designlab and Hammer & Hand are collaborating on a whole house remodel in NW Portland that includes a very unique custom door for the master bedroom.

“The overall design is rather minimal so we were looking for some contrast,” said Alissa Pulcrano, principal of bright designlab. “A focal piece to add drama and make the space one-of-a-kind.”

The new space features a refined palette of black, white, and teak with hot rolled steel accents. Bright designlab tasked Jason Woods, Hammer & Hand finish carpenter, with the challenge of creating a secure door to the master suite reminiscent of vintage fire doors, often seen in NYC warehouses, but with the feeling of a vintage aircraft. The client has an interest in vintage and unusual cars and motorcycles, so the inspiration for the door came from WWII bomber planes and a 1938 Porsche like this one.

“We provided photo inspirations and then let Jason loose to create something above and beyond, like he always does!” said Alissa.

Jason spent hours researching and through Portland-based Columbia Airmotive received invaluable information, rare parts, and inspiration for the door. “With their sharing of stories and personal experiences, I have been able to infuse a sense of historic importance into the door through application of specific accessories,” said Jason. “These parts once flew about on bombers and fighter planes alike, breathing authenticity into the freshly rolled aluminum I have applied secondarily.”

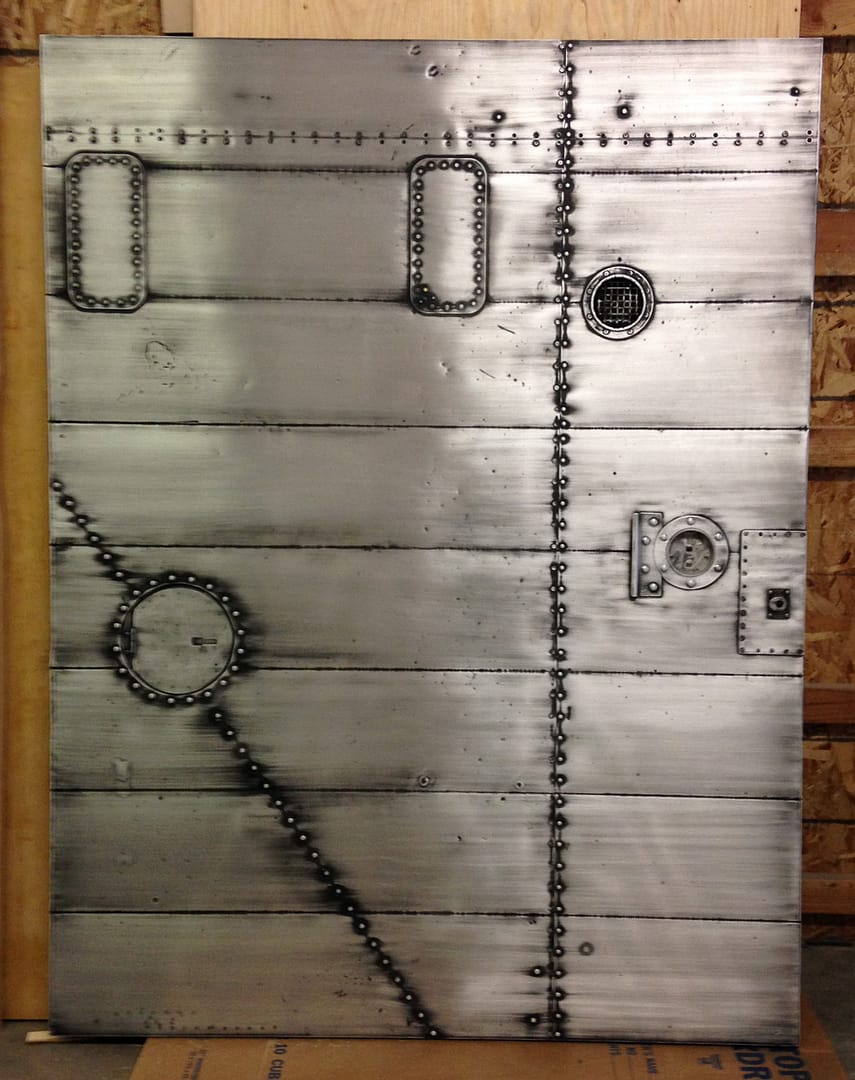

After completing his research and collaborating with Alissa, Jason constructed a small sample door as a way to experiment with different materials and techniques and to show an example to designer and client before beginning work on the real one.

Initial sample door crafted by Jason.

Constructing the Door

H&H’s Dan Palmer and Josh Tinker helped Jason to put together the solid wood bones that rest hidden beneath the aluminum skin of the door. They then cut the wood door to size, routed a bottom channel for the floor guide and kerfed 1/8″ deep horizontal kerfs every ten inches on both sides to accommodate the hand-chiseled creases that would be done later, after the aluminum skinning.

Ultimately, the master suite door will be installed barn-style (hung from above on a roller/rail system) and include special compartments and a locking latch system, so all recesses for components had to be well planned to emulate the look of an airplane. Before applying the aluminum skin, the team distressed all of the sheets of shiny new aluminum to appear vintage. To get an authentic look, the team carefully placed the sheets of aluminum on a solid concrete surface with appropriate texture-lending materials underneath. They then beat and systematically ran over the sheets with a forklift.

After much sanding and buffing, the sheets of aluminum started to hint at past fire fights, complete with numerous bullet-like dents for effect. The sheets were then ready to be cut down to size, routed for accessories, and affixed to the wood slab. From there, it was hundreds of screws and all manner of rivets to hold the sheets in place. “After many hours of experimenting with latches, flaps, and various other items, the door started to take form,” said Jason.

For the finishing touch, Jason applied a faux finish and waxed the door to prepare it for installation. The finished door stands at 61 1/4″ wide, 80 1/4″ tall, and 2″ thick and weighs over 200 pounds.

The entry side of the door in the shop prior to installation.

The master bedroom side of the door.

The master bedroom side of the door.

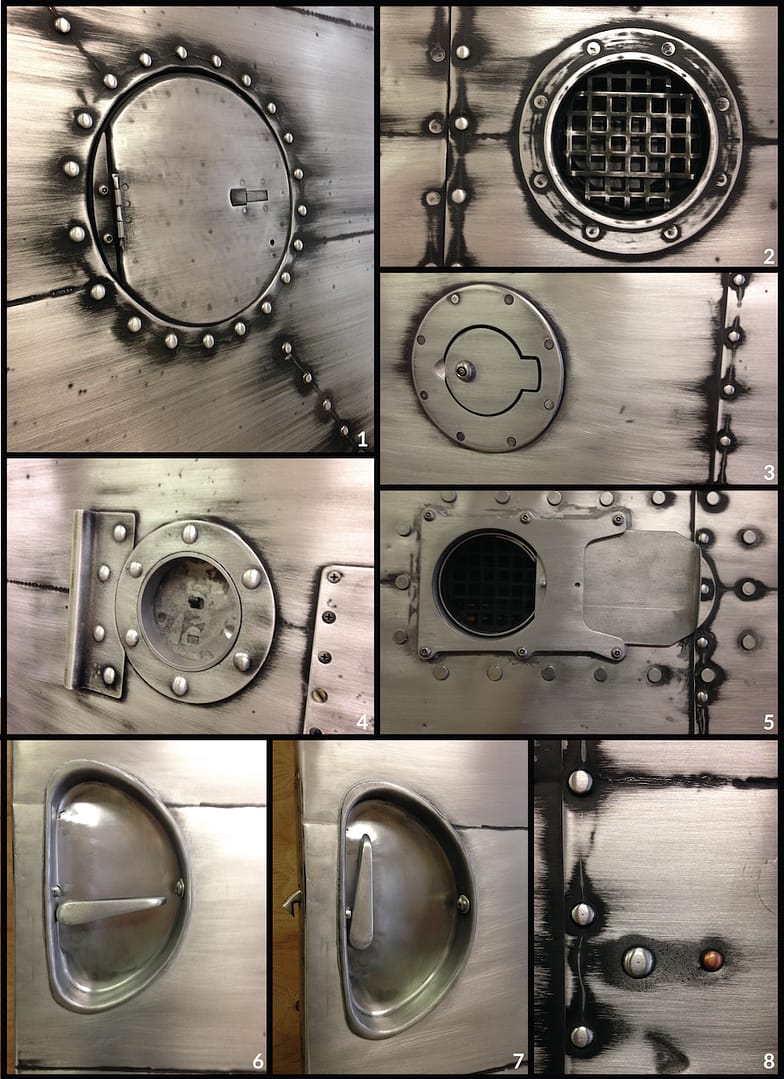

This door has many intricate details built into it for effect:

Details:

Details:

- 9″ diameter salvaged fuel flap from a WW2 plane on entry side.

- Speakeasy shown from entry side. Constructed from WW2 salvage, blast gate and floral grid frog, circa 1940’s.

- Locking compartment, bedroom side. Constructed from a modified racecar gas flap and aluminum baking pan. It is 6 1/2″ in diameter.

- Recessed door pull on entry side made with various WW2 airplane parts.

- Speakeasy shown from bedroom side in open position.

- Recessed door pull on bedroom interior side with pull/locking latch combination in unlocked position. Assembled with standard mortise box hardware customized to accept latch from light reconnaissance aircraft.

- Recessed door pull in locked position.

- Aluminum and copper rivets serve a dual purpose – they hold the aluminum sheeting in place while also serving a decorative function.

The door will be installed soon, we’ll be sure to share updates on this project as it progresses!

Save