Dialing-in the Passive House foundation at Pumpkin Ridge – site pics, and two new videos.

The beauty of the Passive House building energy standard is that it’s totally performance-based. If you can reach Passive House’s three metrics, you’re golden:

- airtightness of less than or equal to 0.6ACH at 50 pascals of pressure.

- annual heat requirement less than or equal to 4.75 kBtu/sf/yr.

- primary energy less than or equal to 38.1 kBtu/sf/yr)

No building components or designs are prescribed. It’s up to the designer and builder and client to come up with the best solution for their given building, site, budget and program.

Advanced building science knowledge combined with powerful modeling tools like the Passive House Planning Package (PHPP), WUFI, and Therm make it possible, enabling project teams to find the right balance of architecture, budget, and materials for the client.

Want lots of glass and articulation in the envelope? That’s doable, it just means that other parameters of the design will need to adjust to offset. Architects and clients absolutely have the leeway to play and create high design expressions of Passive House.

The Karuna House, designed by Holst Architecture, is a beautiful example of this. It breaks out of the stereotypical “shoe box” mold, plays with cantilevered forms, and incorporates walls of glass to take advantage of sweeping views of the surrounding vineyard landscape. Carefully designed wall assemblies, thick layers of insulation, and high performance windows and doors will enable the home to meet the performance requirements of Passive House. As we’ve chronicled in a previous post, Karuna is set on top of a 12″ layer of EPS geofoam, its thickness partly dictated by the home’s articulation.

The Karuna House, designed by Holst Architecture, is a beautiful example of this. It breaks out of the stereotypical “shoe box” mold, plays with cantilevered forms, and incorporates walls of glass to take advantage of sweeping views of the surrounding vineyard landscape. Carefully designed wall assemblies, thick layers of insulation, and high performance windows and doors will enable the home to meet the performance requirements of Passive House. As we’ve chronicled in a previous post, Karuna is set on top of a 12″ layer of EPS geofoam, its thickness partly dictated by the home’s articulation.

The Pumpkin Ridge Passive House is also a beautifully-designed home, this one by Scott | Edwards Architecture. But budget was a critical consideration for this project. In fact, the home’s been designed to be no more expensive on a monthly basis than a conventional custom house. So the designers kept the form of the building simple, with few articulations. The modest surface to volume ratio that this affords means less heat loss and therefore a smaller demand on the performance of the building envelope. Translation: less EPS foam required under the structure.

The Pumpkin Ridge Passive House is also a beautifully-designed home, this one by Scott | Edwards Architecture. But budget was a critical consideration for this project. In fact, the home’s been designed to be no more expensive on a monthly basis than a conventional custom house. So the designers kept the form of the building simple, with few articulations. The modest surface to volume ratio that this affords means less heat loss and therefore a smaller demand on the performance of the building envelope. Translation: less EPS foam required under the structure.

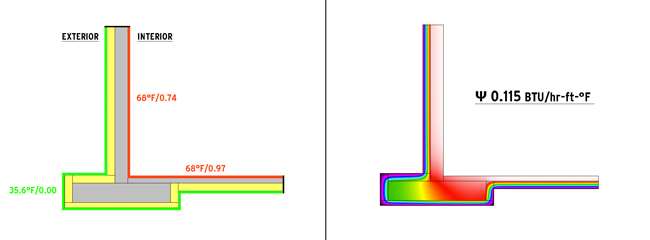

I spoke this morning with Skylar Swinford, Certified Passive House Consultant and building energy expert at Hammer & Hand, about the details. Skylar and the team employed PHPP and the two-dimensional heat transfer modeling software called Therm to optimize the design. In contrast to the Karuna house where we used 12″ of EPS under the slab and under the footings. At Pumpkin Ridge we’ll use just 6″ under the slab and 4″ under the footings. (See second video below for more.) Less EPS foam means less cost and less embodied energy.

Therm calculation of Pumpkin Ridge Passive House foundation.

“Part of it is the simpler form,” said Skylar. “But part of it is that we’re getting better at optimization, both at H&H with every Passive House project we do, and as a larger movement. It is amazing how rapidly Passive House is evolving in North America. We’re now hitting our stride.”

And just as our design optimization is improving, so are our construction methods. With fall rain approaching, time has been of the essence at Pumpkin Ridge Passive House recently. Gotta get that foundation poured. So rather than use the more time-intensive compacted gravel bed strategy under the EPS geofoam, the Pumpkin Ridge team opted for a bed of “flowable fill” (aka “controlled-density fill” or “liquid soil”.)

Photo Tour

Skylar also took some nice photos documenting the process. See his pics and caption notes:

Peter Bogart and Val Darrah screed the flowable fill for a perfectly level surface. The temporary wood formwork doubles as a screed rail.

Simple formwork for the flowable fill installs quickly.

Final stretch!

Once cured, the flowable fill creates a dead level surface for installing geofoam and footing forms.

The flowable fill is delivered by a concrete mixer truck and is pumped down to the building site with a long hose.

The large sheets of geofoam lay down quickly over the cured flowable fill.

View of cured flowable fill from above. Geofoam installation in progress.

The footing forms are standard box forms and will be installed directly over the geofoam.

There’s lots more to share about Pumpkin Ridge Passive House – from Zola windows to plugging the metaphorical leaky bucket to busting the super-chunky Passive House myth. Please stay tuned!

– Zack

P.S. Here are some technical specifics from Skylar on the geofoam and flowable fill we’re using at Pumpkin Ridge:

Geofoam: Under the footings we are using 2.40-2.50 lb/ft3 EPS39 (Geofoam title) or Type XIV (EPS title). Under the slab we are utilizing 1.35 -1.50 lb/ft3 EPS22 or Type II.

Flowable Fill/Controlled Density Fill (CDF): CDF also known as, flowable fill or liquid soil has been used for decades as a self-compacted structural backfill. Flowable fill is primarily used in trenches or other tight areas where it is difficult or dangerous to place and compact traditional fill. Similar to concrete, flowable fill can be ordered from standard ready-mix concrete suppliers and is composed of water, sand, portland cement, and fly ash.

There are flowable fill mixtures than can provide compressive strength upwards of 1,200 psi, but the mixture used on this project is the 250 psi variety which still far exceeds our needs.

Back to Field Notes