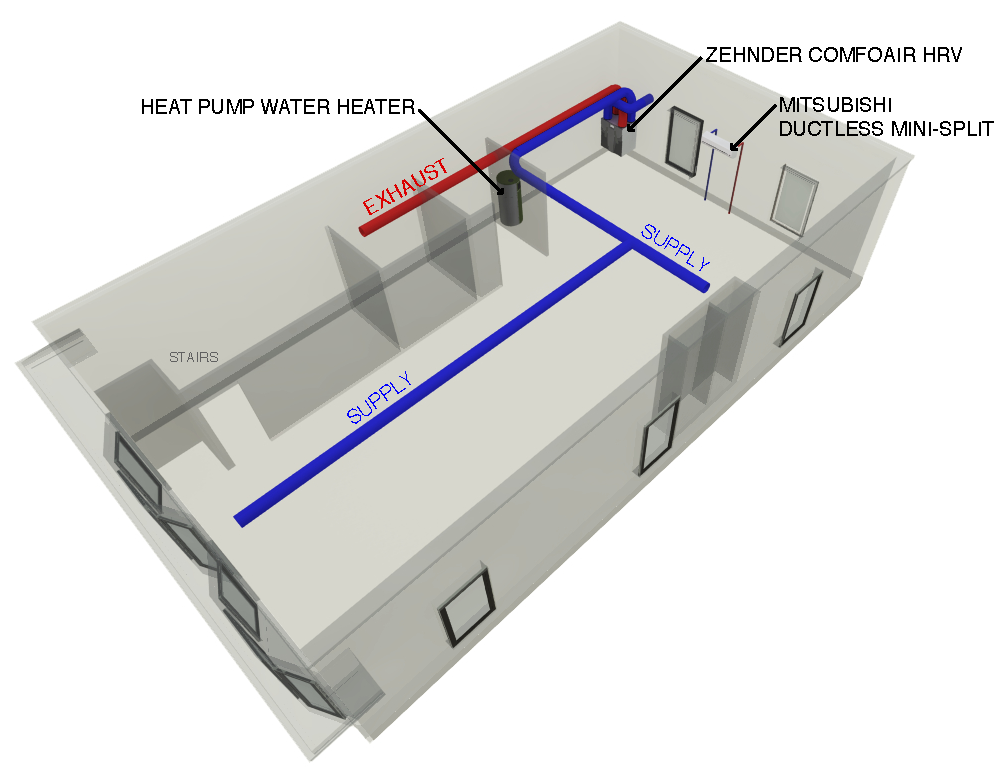

Mechanical Systems

The mechanical system strategy at Glasswood became one of the simplest elements of the project, thanks to the micro-loads of Passive House. The space is ventilated using an 88% efficient Zehnder 550 ComfoAir HRV, controlled by a carbon dioxide sensor that modulates the ventilation rate depending on occupancy. The unit maximizes the cooling potential through night flush ventilation. In this mode the HRV bypasses the heat recovery core and exchanges all the air in the building a number of times with outside air, effectively lowering the temperature inside the building to that of the exterior in cooling demand situations.

A heat pump hot water heater, programmed to run afterhours, provides domestic hot water for the lavatory and kitchenette. During summer months this unit partially offsets the space’s cooling load by pulling heat from the interior air. During winter months the unit switches over to electric resistance heat to avoid cooling the space. Heating and cooling is provided by one Mitsubishi ductless minisplit. The design at Glasswood incorporates open space, natural light, and high quality, efficient artificial lighting. The daylighting scheme for the space includes three daylighting zones equipped with sensors that monitor daylight and occupancy so that artificial lighting adjusts automatically to the natural light provided by the space’s large high performance windows. Initial modeling of conventional lighting systems showed the lighting satisfying the entire heating load during winter and leading to excessive cooling load in summer, so daylighting and use of efficient fixtures were key to the Passive House strategy.

The design at Glasswood incorporates open space, natural light, and high quality, efficient artificial lighting. The daylighting scheme for the space includes three daylighting zones equipped with sensors that monitor daylight and occupancy so that artificial lighting adjusts automatically to the natural light provided by the space’s large high performance windows. Initial modeling of conventional lighting systems showed the lighting satisfying the entire heating load during winter and leading to excessive cooling load in summer, so daylighting and use of efficient fixtures were key to the Passive House strategy.