The Passive House, Minergie-P-ECO, LEED Platinum project is now officially “out of the dirt.”

Lead Carpenter Scott Gunter and Project Administrator Shelley Martin video-conferenced with me today from the job site in Yamhill County to share the latest progress at the Karuna House, the national green building case study designed by Holst Architecture and built by Hammer & Hand.

The team has been busy prepping and pouring the upper floor and basement concrete slabs. Scroll on for Shelley’s photos and Scott’s notes.

Upper floor slab pour

We start with the pour of the slab for the upper floor of the Karuna House…

Here the blue air/vapor barrier is in place, hiding a thick layer of super-insulating EPS geofoam that lies underneath. As you can see at right, the blue barrier wraps up and over the stem walls, which are also clad in EPS foam. The rebar grid and formwork are ready and waiting for the concrete in this photo, taken just 10 minutes before the pour.

This photo shows how the team dealt with pipe penetrations through the air/vapor barrier: everything taped with a butyl-based tape and coated with air-sealing mastic.

Here the pump truck is pouring the concrete slab via its boom. We’re using the same LEED-friendly 30% fly ash concrete mix that we discussed in our last Karuna post, with the locally-sourced aggregate.

Here’s a nice shot of the upper floor slab after the pour. Notice the under layer of EPS geofoam extending out beyond the slab and stem walls, insulating the future home from the heat-robbing ground.

Sill plate detailing

Next we move on to the sill plate details, showing how the team negotiated the transition from the concrete stem walls to the wood framed walls that will be built atop them…

This shot shows a stem wall with the wood sill plates resting on the ground, waiting to be placed. Notice how the blue air/vapor barrier transitions right to the top of the stem wall. We’re using the same taping and mastic treatment for the penetration of the J bolts as we did for the pipe penetrations discussed earlier.

This photo shows how the EPDM gasket has been applied to the bottom of the wood sill plate. This gasket will create an airtight seal between the bottom of the sill plate and the top of the stem wall.

In conventional construction, you’d instead use a pressure-treated sill plate here to interrupt moisture transfer from the concrete foundation wall to the wood framing above, with a layer of off-the-shelf sill sealer applied between the sill plate and the stem wall. No vapor/air barrier, no mastic, no EPDM gasket. But pressure treated lumber is prohibited by the Minergie-ECO standard, so that would be a no-no at Karuna. And because we have a vapor barrier enveloping the stem wall, there’s no moisture transfer from the stem wall and therefore no reason to use a pressure treated sill plate in the first place.

Here’s a detail of the sill plate installed atop the stem wall with the EPDM gasket providing the airtight seal.

Basement pour

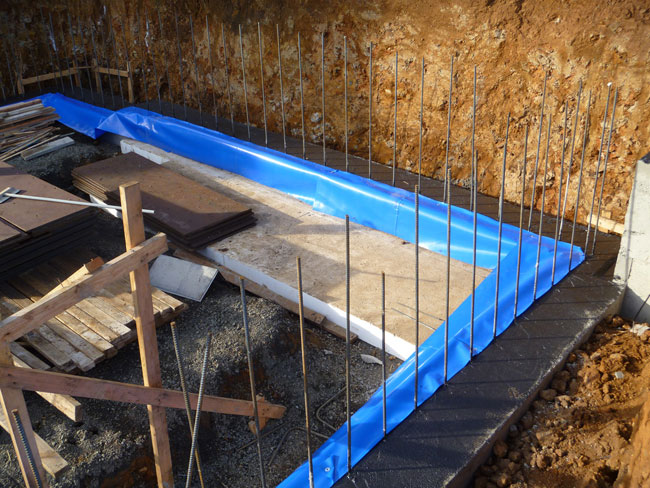

In the final set of photos we’re on to preparations for the pour of the basement slab…

This shot shows the black capillary break material (discussed in our last Karuna post) applied atop the footing. The blue air/vapor barrier is aligned with the vertical pieces of the rebar for the stem wall. We cast the stem wall on top of this air/vapor barrier to create an airtight seal.

In this shot the stem walls have been poured and the air/vapor barrier for the basement slab is taped and sealed. The trench that is visible along the left will create a thickened portion of the slab for a load-bearing wall. The vertical pipe and square bare patch on the right is for the basement’s sewage ejector pump. It will be an entirely self-contained, air-sealed and insulated system, completely isolated from the house.

Here the rebar grid is ready for the pour.

This shot shows the basement slab awaiting its pour, and the finished upper slab above. Concrete is nearly complete!

“Now we’re ready to start framing,” Scott told me. “We’re out of the dirt!”

– Zack

Back to Field Notes